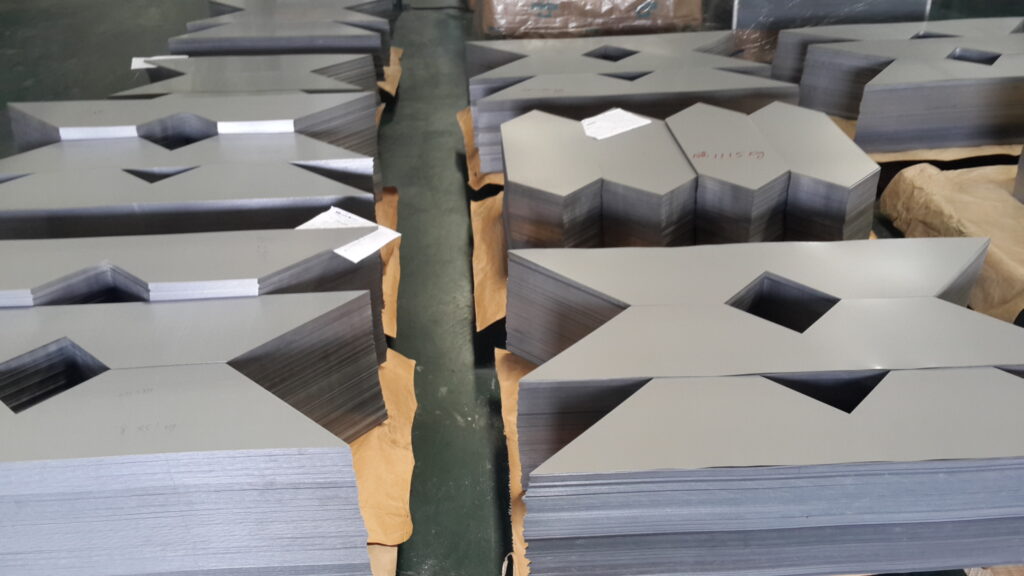

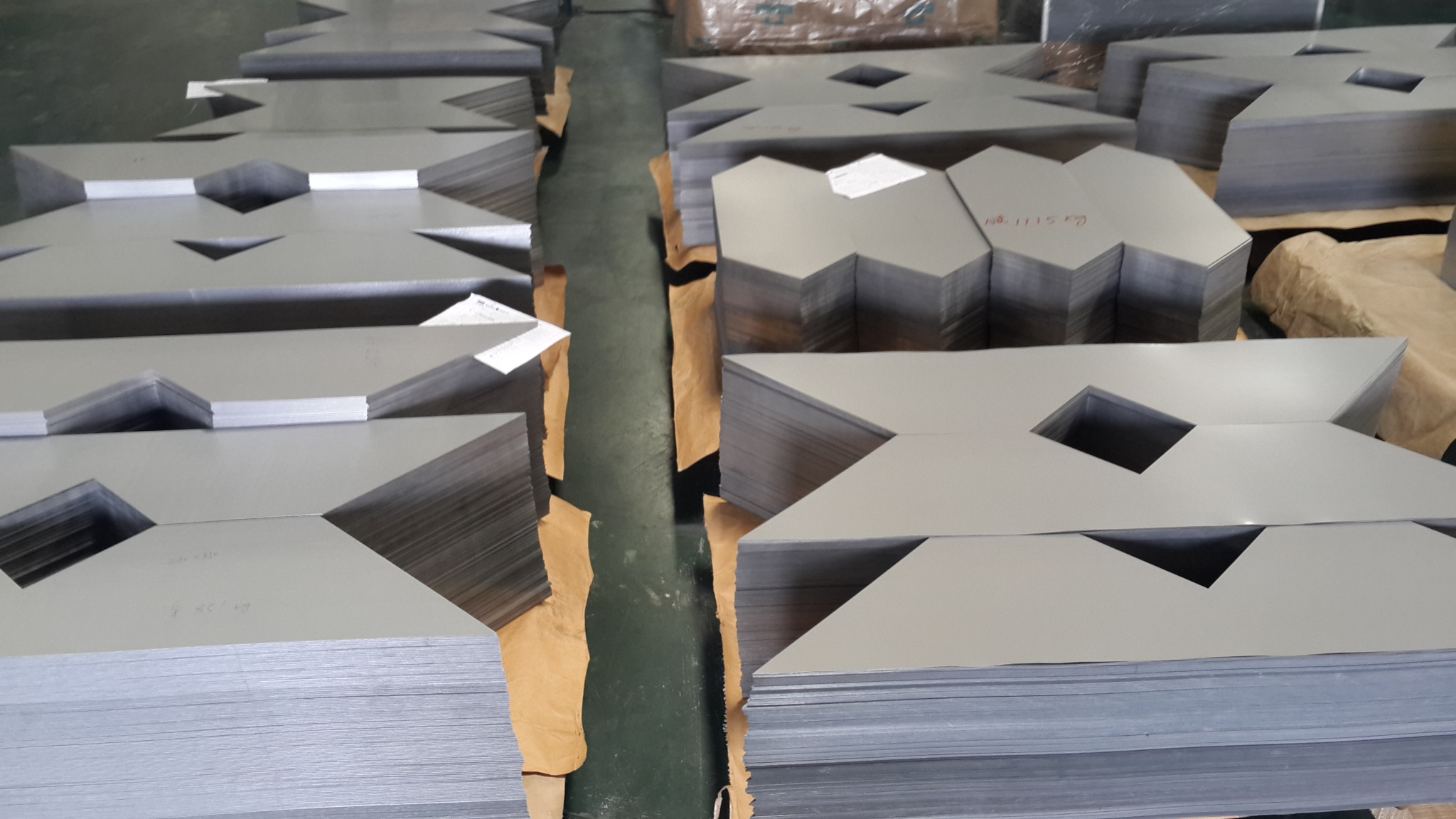

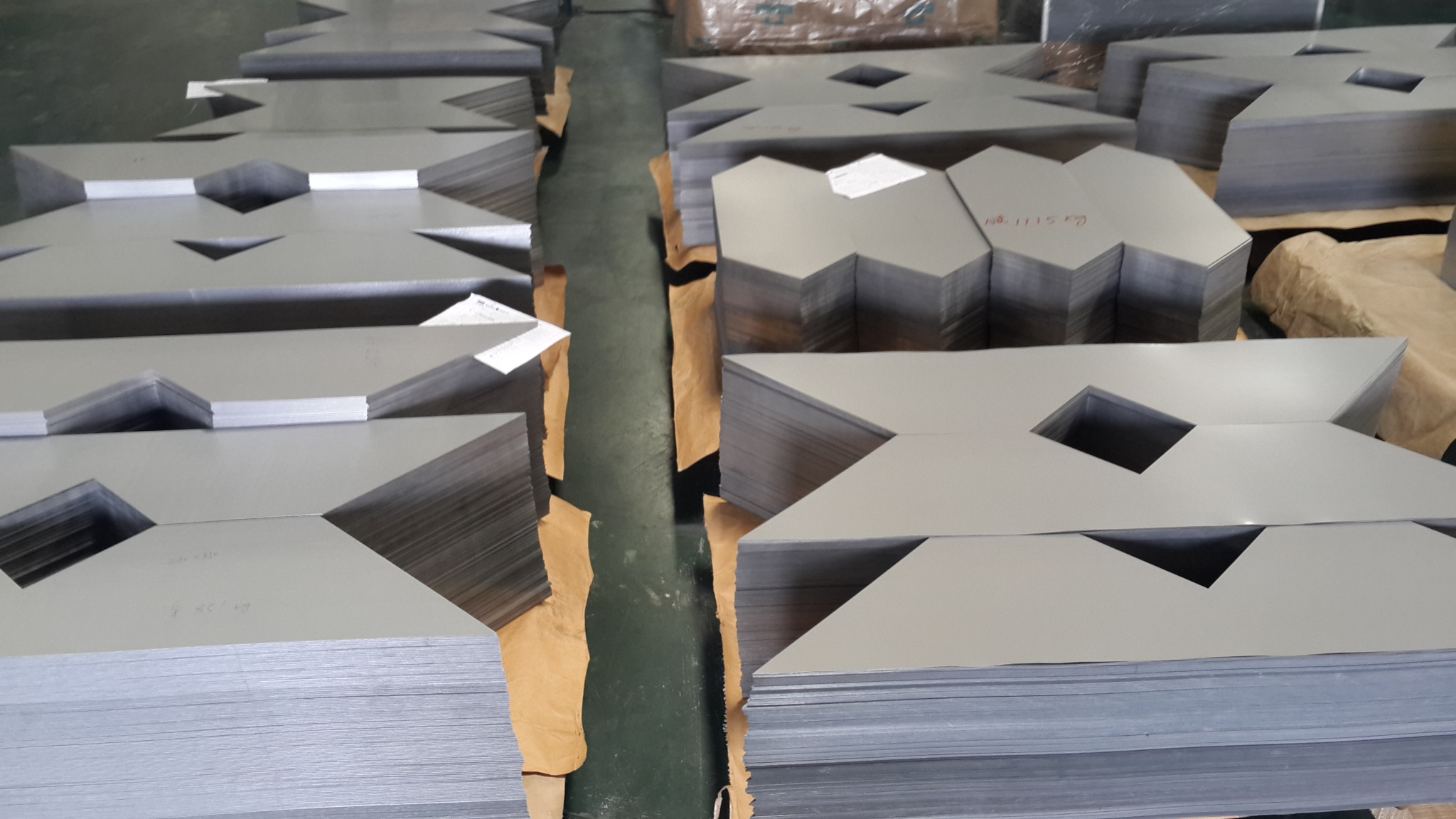

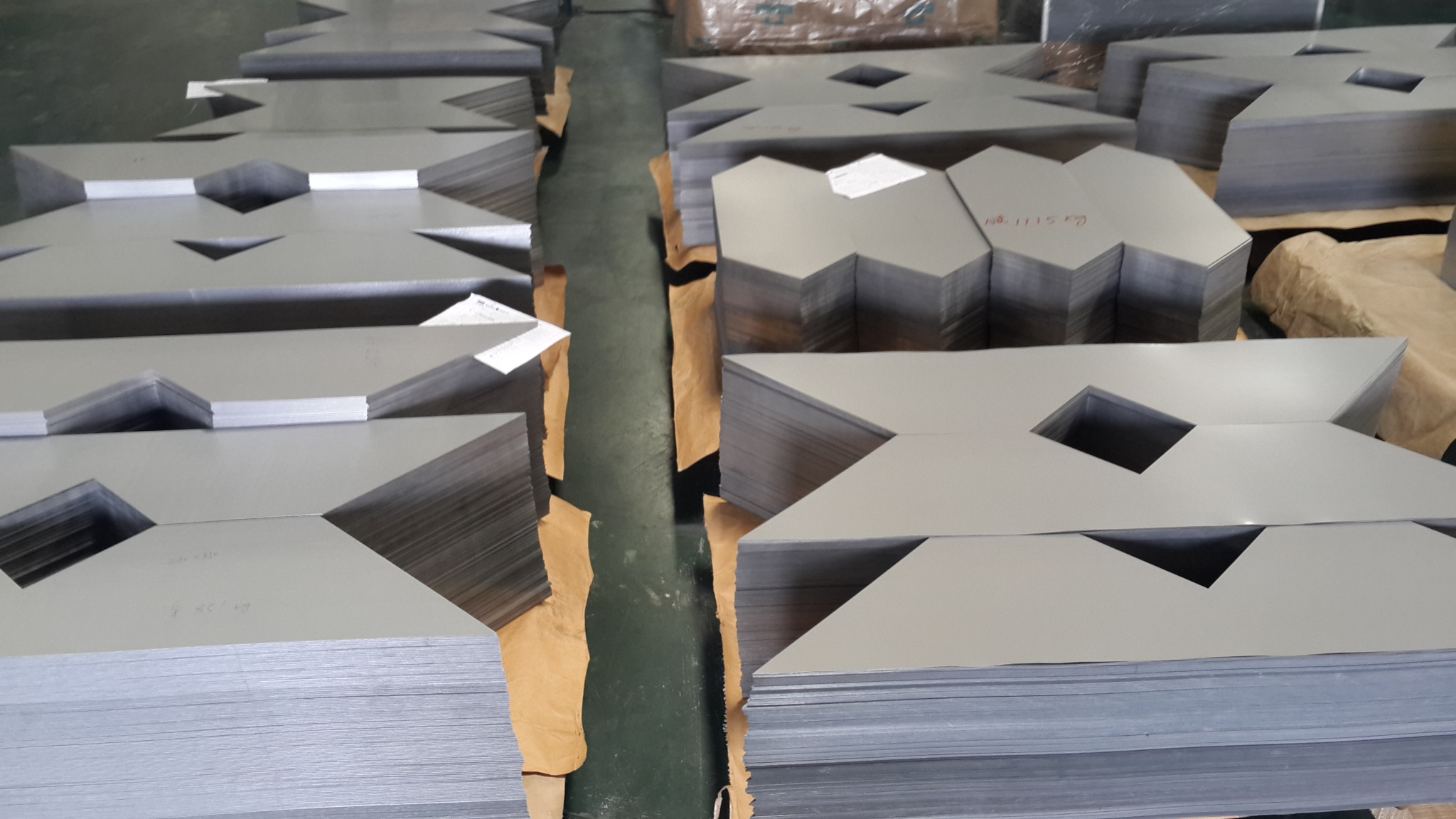

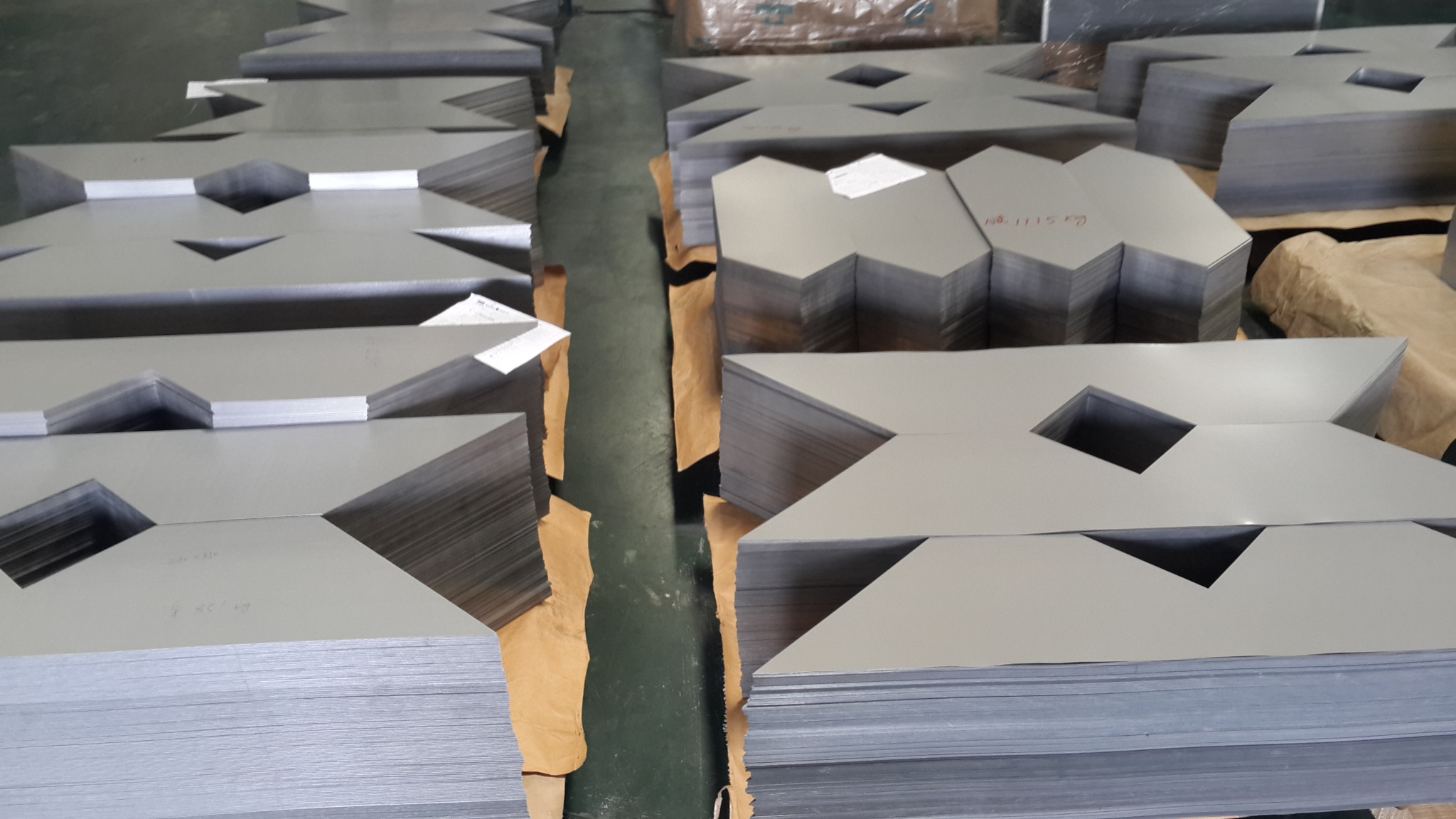

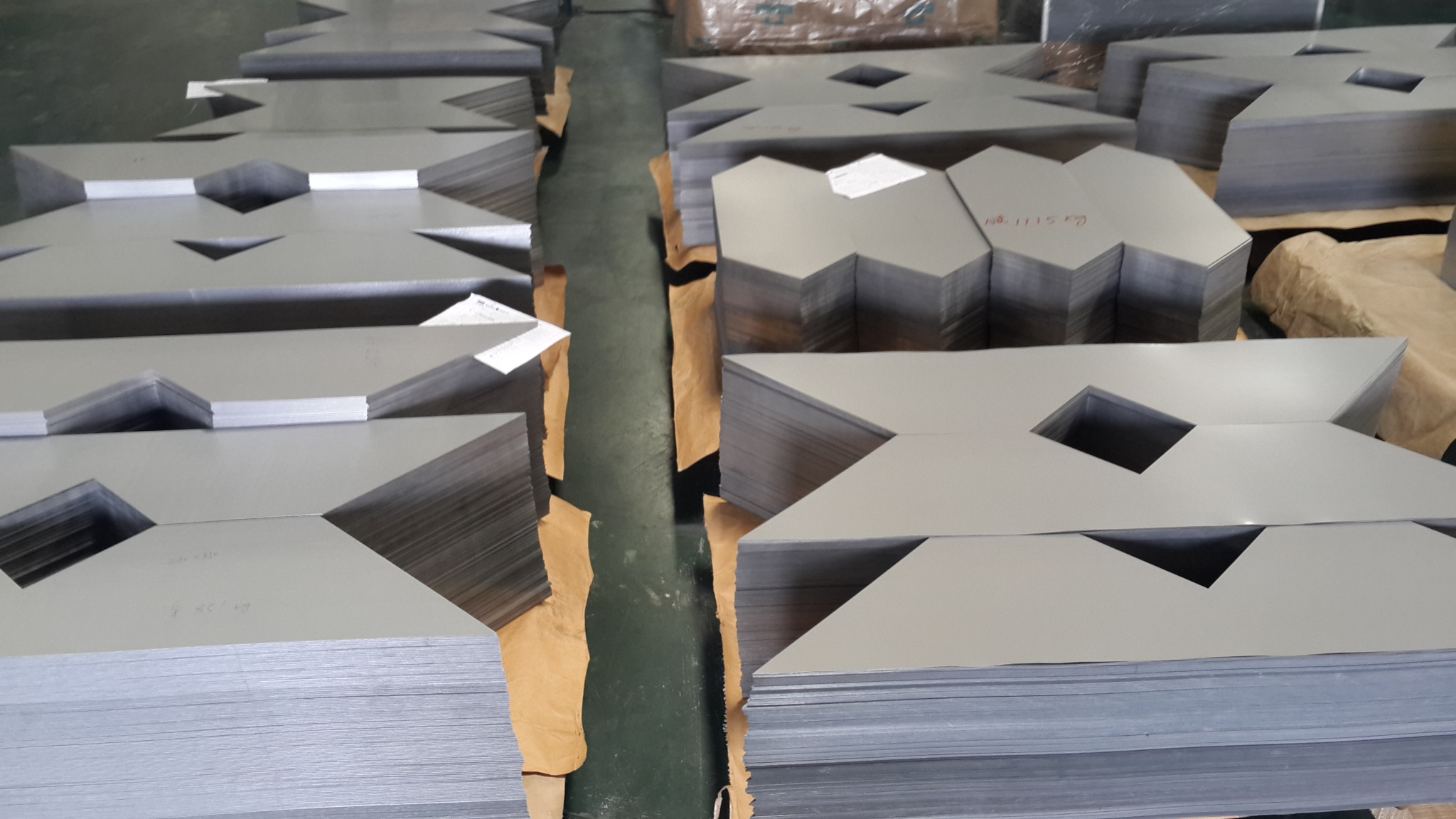

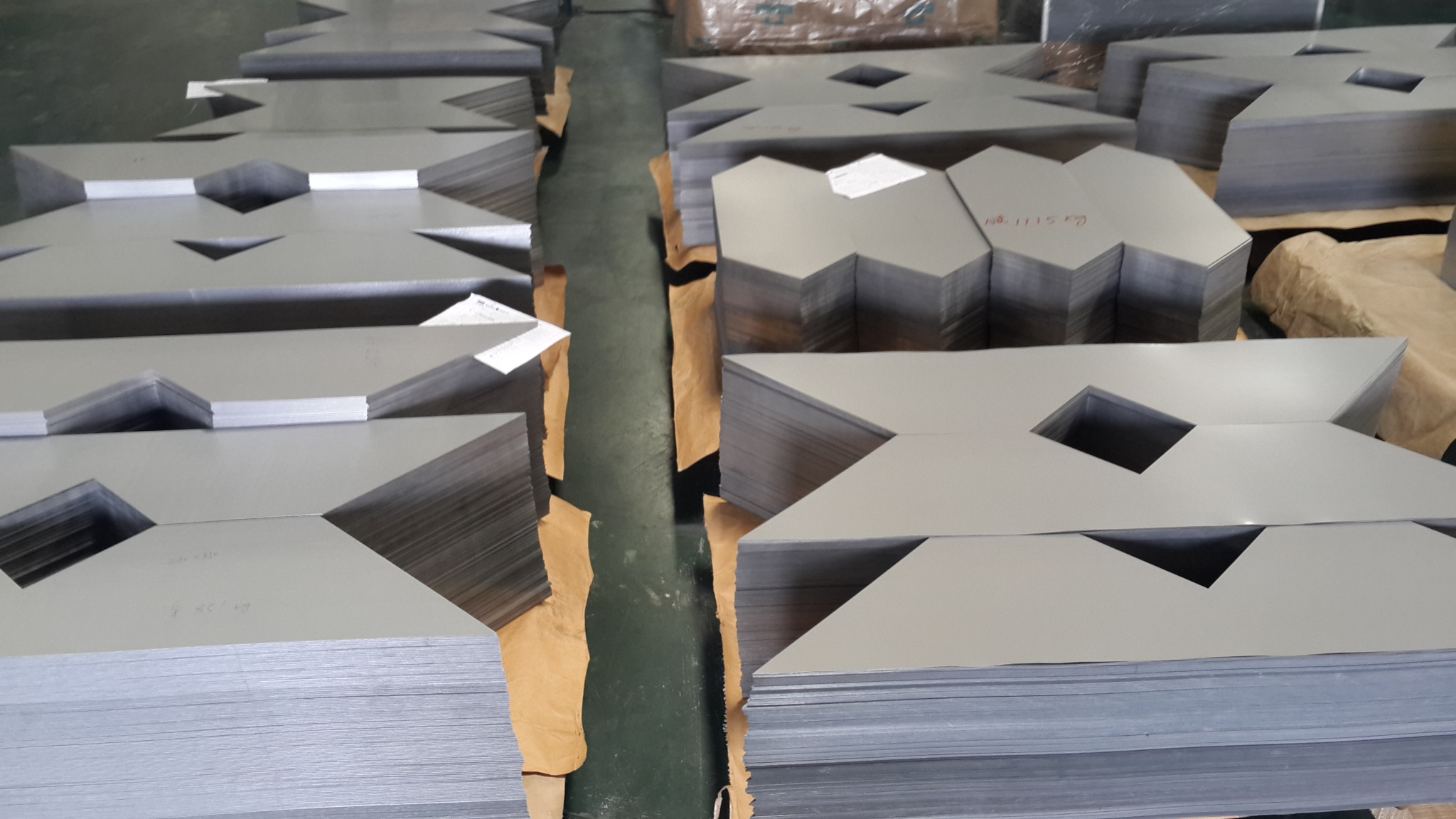

CRGO Electrical Steel Transformer Lamination

- For power & distribution transformers up to 100 MVA.

- With guaranteed losses.

- Step-Lap cores in Completely automated CNC cut to length lines

Complete Assembled cores :

- As per the design required by our customers.

- With achieved losses.

- Very job tested with No Load Losses

- Complete traceability of material and testing record

- Up to 20 MVA size transformer

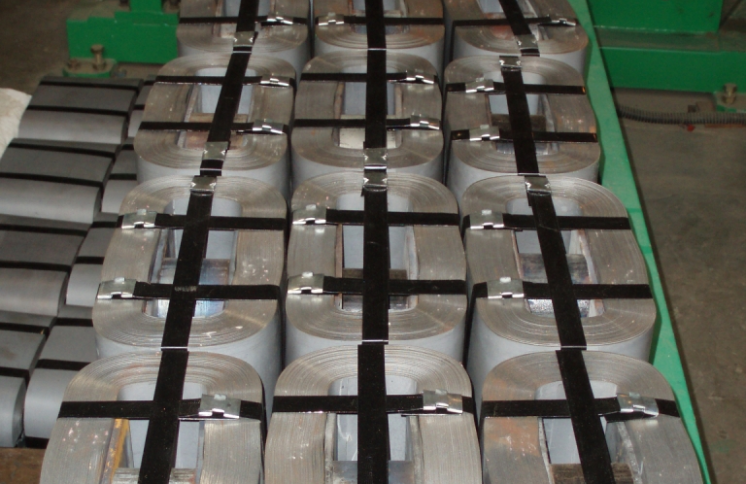

CRGO Electrical Steel in coils/Slit coils:

- All grades of CRGO steel available.

- With test certificates.

- By state of the art, Automated Laser guided Slitting line with tungston carbide.

CRGO Wound core/GAP CORE :

- As per the design required by our customers.

- With achieved losses.

Cold Rolled Grain Oriented electrical (CRGO) is used for manufacturing for Laminations and Wound Cores:

Various grades of CRGO steel such MOH23, M3, M4, M5, M6 , HI-B , TCHO/ THCI, MOH27 etc

Properties of CRGO and Tolerance of Laminated core »

CRGO Electrical Steel Transformer Lamination

- For power & distribution transformers up to 100 MVA.

- With guaranteed losses.

- Step-Lap cores in Completely automated CNC cut to length lines

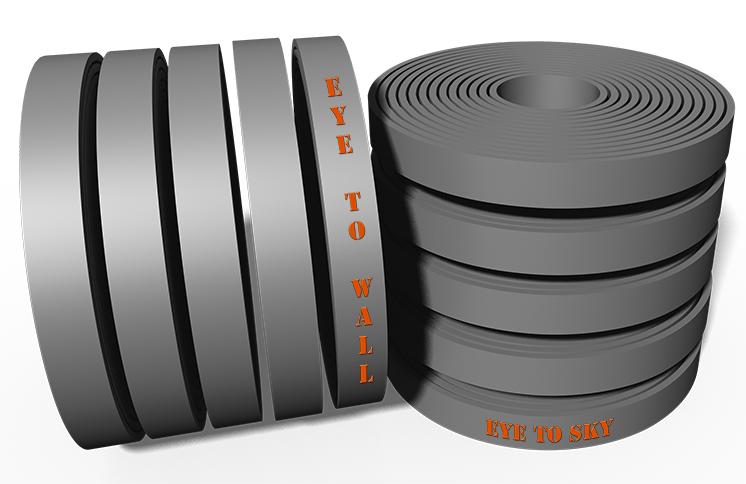

CRGO Electrical Steel in coils/Slit coils:

- All grades of CRGO available.

- With test certificates.

- By state of the art, Automated Laser guided Slitting line with tungston carbide.

CRGO Electrical Steel Transformer Lamination

- For power & distribution transformers up to 100 MVA.

- With guaranteed losses.

- Step-Lap cores in Completely automated CNC cut to length lines

CRGO Electrical Steel in coils/Slit coils:

- All grades of CRGO available.

- With test certificates.

- By state of the art, Automated Laser guided Slitting line with tungston carbide.

Complete Assembled cores :

- As per the design required by our customers.

- With achieved losses.

CRGO Wound core/GAP CORE :

- As per the design required by our customers.

- With achieved losses.